MORE THAN JUST A PIECE OF WOOD: UTILITY POLES

Africa's landscape paints a picture of rolling mountains, beautiful rivers, oceans and a stunning variety of vistas. Wherever you travel, the streets, rolling hills and valleys are dotted with the consistent aesthetic of utility poles connecting nations with power and breathing electricity into the household of millions. Many overlook the unexpected quality of the process behind these utility poles that make them more than just a piece of wood.

Some things you didn't know:

In South Africa we call them utility poles but if you ask around the world you may hear names such as electric poles, telephone poles, power poles, hydro poles or telecommunication poles to name a few.

The trees used for utility poles take 12 years of farming, growing and grooming before they are harvested. This means that the trees planted at R&B timbers today will be used for many generations to come.

R&B Group manufactures large-scale exports of utility poles throughout Africa as well as internationally. Imagine how many of these have been standing tall around the world.

One of the biggest issues with wooden utility pole production is the transportation and export of such a large and heavy quantity. The R&B Group differentiates from this due to our easy access to the harbors of the South African East coast, which makes shipping to any destination cost effectively simple.

R&B Group specializes in the manufacturing, large-scale order and export of utility poles throughout Africa, and globally. Our easy access to the harbors of the South African East coast make shipping them to any destination simple.

Once properly treated, utility poles can last a really long time with an average life span of 40 to 60 years.

Did you know the first telephone pole was built in 1876 for a friend of Alexander Graham Bell's employer?

One of the most unique electricity poles can be found in Florida near the Western exit of the Walt Disney World resort. The pole depicts the iconic symbol of Mickey Mouse.

All timber utility poles need to be treated using a creosote or CCA process to protect them from pest, insect and fungi infestations.

There are even laws surrounding the use of these poles. If you're ever in the Southern capital of Atlanta just know that it is illegal to hitch a giraffe to a utility pole or street lamp.

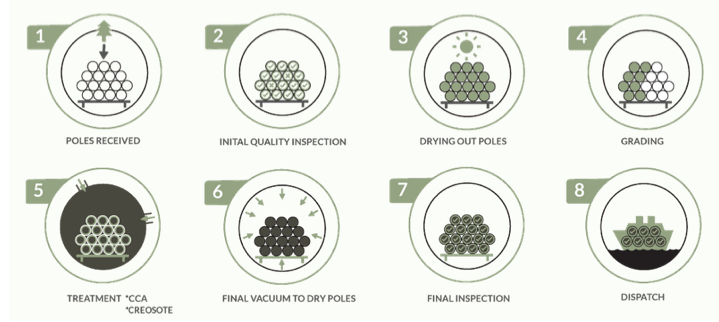

Each and every pole goes through a specialised 8-step process to ensure exceptional quality that lasts for years.

All R&B Group utility poles are manufactured under ISO9001 certification & to the stringent SABS 754 quality controls. The R&B Group makes every effort to ensure maximum quality in the processes and treatments of our utility poles for our customers. That's what makes our utility poles more than just a piece of wood.